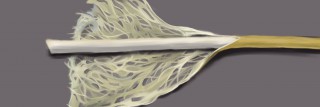

Primary Fiber

Mechanical peeling of the outer bast replaces the ancient (& current) practice of producing high-quality fiber. Degummed by the same machine that peels off the bast & having the potential to work in the field is the innovation needed to ramp up primary hemp fiber production in North America & now Mexico!