Experiments began with a mechanical way of extracting the outer fiber on the eve of 2012. By late 2012, the term ribbon decortication was coined. By 2014, a maturing hemp grain market still did not have any Canadian fiber processing capacity & the US had opened the door to hemp production. By utilizing post-seed/fiber hemp since the onset of research, we discovered that dual strains worked just as well as fiber-only crops. For composite uses, harvesting male-only plants makes no sense. With proper enzymatic treatment, textile quality fiber can be achieved, validated by the NRC’s advanced biomaterials division in 2015.

Check out our first white paper on this important topic; Ribbon Decortication paper

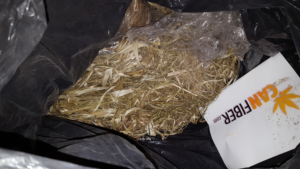

The design evolved rapidly to address the need to feed it at a speed that was commercially viable. What came out was a design that allowed for degumming the ribbon before shooting it into an onboard round baler. Canfiber’s RD technology exploits the high tensile strength of the outer fiber, allowing for a low energy footprint to operate the system.

Designing a piece of equipment that can handle the shear volume of stalks was no easy task & required the coming together of very bright individuals to help see this through. Thank you all for your contributions in helping RD technology evolve for the benefit of all humanity. You are not forgotten.